Ever wonder what happens when you press the gas pedal and your car tumbles forward like an obedient mechanical beast? Understanding how gasoline engines work pulls back the curtain on a neat mix of chemistry, precision metal motion, and tiny controlled explosions that power much of our world.

The heart of the engine: cylinders and pistons

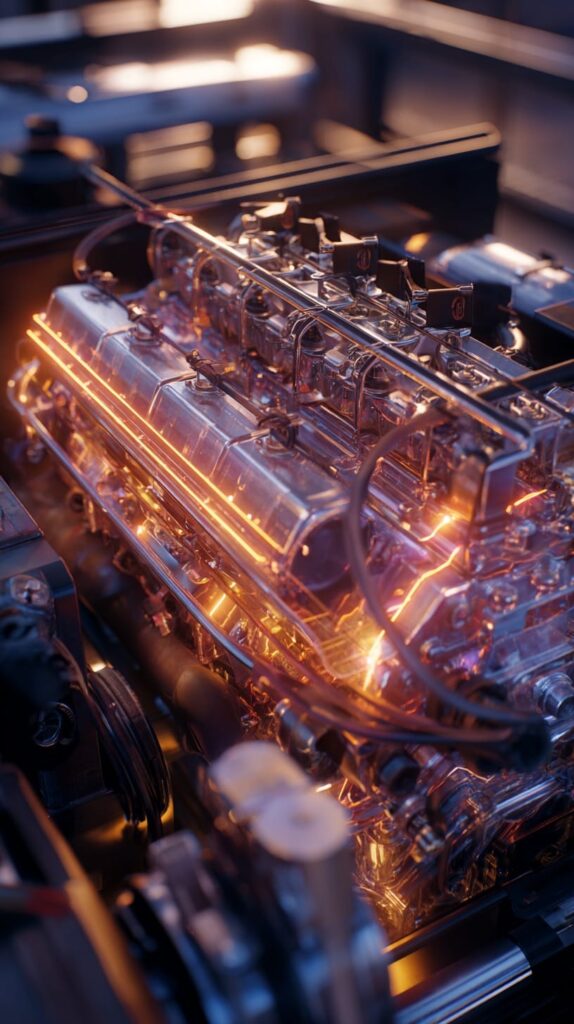

At its simplest, a gasoline engine is a set of cylinders with pistons that move up and down. Each piston is a metal plug that fits tightly inside a cylinder and seals a chamber where fuel and air meet.

When the mixture inside that chamber ignites, it creates pressure that pushes the piston down, and that linear motion is what eventually turns the wheels via the crankshaft.

The four-stroke cycle explained

Most gasoline engines are four-stroke internal combustion engines, meaning each cylinder completes four steps: intake, compression, combustion (power), and exhaust. These steps repeat thousands of times per minute in a running engine.

During intake, the piston moves down and a valve opens to let in a precise fuel-air mixture. Next, the piston rises to compress that mixture; higher compression makes the blast more energetic.

At the top of the compression stroke a spark plug fires, igniting the gasoline-air mix for the power stroke. The hot expanding gases shove the piston down, and finally the exhaust valve opens to clear the burned gases so the cycle can begin again.

How fuel and air get there: carbs vs. fuel injection

Older engines used a carburetor to mix gasoline and air, but modern engines almost always use fuel injection for better efficiency and control. Fuel injectors spray precise amounts of gasoline directly into the intake air stream or the combustion chamber.

The throttle controls how much air—hence how much fuel—enters the engine, letting you accelerate or idle. Electronic control units now manage injection timing and quantity for cleaner combustion and improved fuel economy.

Ignition and timing

Sparking the fuel mixture at the right moment is crucial. If spark comes too early or too late, the engine runs poorly or can even suffer damage. Engineers carefully set ignition timing for each operating condition.

Modern systems use sensors and electronic ignition to adapt timing as speed, load, and fuel quality change. Proper timing helps reduce knocking and improves power and efficiency.

From linear motion to rotation

Pistons move up and down, but wheels spin. The crankshaft converts the pistons’ linear movement into rotation using connecting rods and carefully phased motion. That rotation travels through the transmission and finally to the drive wheels.

Multiple cylinders fire in sequence to keep power smooth and continuous. Engine balance, firing order, and crank design all matter for vibration, smoothness, and performance.

Cooling, lubrication, and durability

Combustion produces heat, so engines use coolant running through jackets around the cylinders and oil to lubricate moving parts. Without these systems, parts would seize or warp quickly.

Oil reduces friction and carries away heat while also protecting metal surfaces. Regular maintenance—changing oil and coolant—keeps the engine running smoothly and extends life.

Exhaust, emissions, and efficiency

Burning gasoline creates gases that must be cleaned before they escape. Modern engines pair catalytic converters, oxygen sensors, and exhaust design to reduce harmful emissions like carbon monoxide and nitrogen oxides.

Engineers also chase higher thermal efficiency—extracting more useful work from each drop of fuel—by optimizing compression ratio, combustion chamber shape, and fuel delivery.

Where gasoline comes from and why it matters

Gasoline is a refined product of crude oil, pulled from underground reservoirs using machines like pumpjacks and then processed into a fuel that burns cleanly in engines. The quality and additives in gasoline affect performance and emissions.

Curious about gasoline itself? The tint and additives in fuel can vary, and a closer look at the color of gasoline explains some of those differences and what they mean for your engine.

Safety note: gasoline is reactive

Gasoline is volatile and flammable; mixing it with odd chemicals can be dangerous. For a deeper look at risky combinations, see the discussion about mixing gasoline and hydrogen peroxide to understand why caution matters.

Quick tips to keep a gasoline engine happy

- Change oil on schedule to protect moving parts.

- Replace air and fuel filters to keep the fuel-air mix clean.

- Use the right octane fuel for your engine to prevent knocking.

- Check cooling system and belts to avoid overheating.

These small habits go a long way toward maintaining good compression, clean combustion, and dependable starting—three things every driver appreciates.

Why learning this matters

Knowing how gasoline engines work turns random anxiety about “mysterious engine noises” into informed troubleshooting and smarter maintenance decisions. It also helps you appreciate the clever engineering behind engines that cram a lot of power into a compact, moving package.

Whether you’re fascinated by pistons, curious about emissions, or just trying to be a better car owner, the principles of the internal combustion engine offer a tidy mix of physics, chemistry, and craftsmanship.